log in for your price

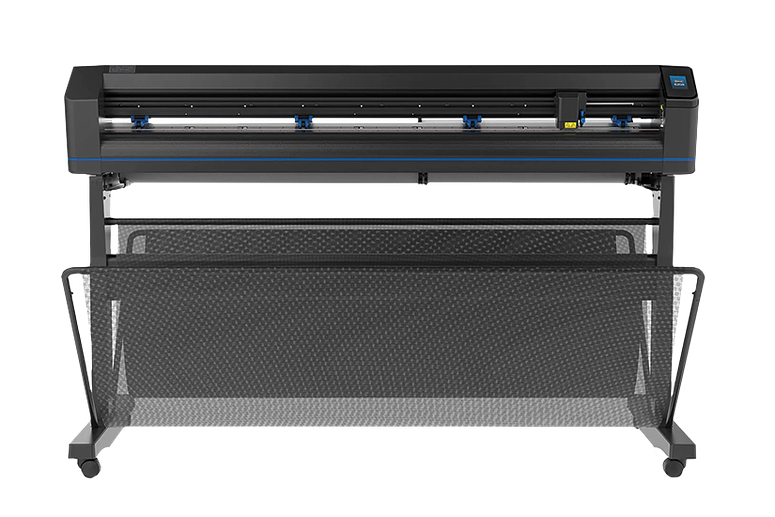

Summa S One D140FX

Summa S One cutting plotter with drag knife technology and fixed pinch roller positions for cutting up to 144,5 cm wide

4,521.70

Product information

The Summa S One D140FX is a Summa S One cutting plotter with fixed pinch roller positions for cutting up to a width of 144,5 cm. Many applications can be handled with this cutting plotter, whether it is precision cutting laminated vinyl to flock and flex materials, sandblast films or other challenging material types. The Summa S One D140FX is equipped with GoSign software, a durable drag knife cutting head and OPOS X technology for automatic contour cutting of full colour print work.

- The Summa S One series combines power and precision with an efficient, affordable and fast drag knife cutting head.

- The OPOS-X contour cutting system allows you to cut printed media with complete confidence and ease.

- Excellent, reliable cutting quality over longer lengths of material is guaranteed.

- Has fixed pinch roller positions for nine base widths, meaning any media format can be loaded, but margins cannot be minimised. This makes this cutter especially suitable for contour-cutting prints.

Features

Product specifications

-

BrandSumma

-

Dimensions1.765 x 704 x 1.112 mm

-

Weight43,5 kg

-

Cutting range1.445 mm

-

Cutting force400 gr

-

Speedmax. 1131 mm/s diagonal

Attachments

Videos